PIPELINE EXTERNAL CORROSION MAPPING

ITS have the experience and expertise to ensure internal or external deterioration is accurately measured and assessed.

3D HANDYSCAN LASER CORROSION SCANNER

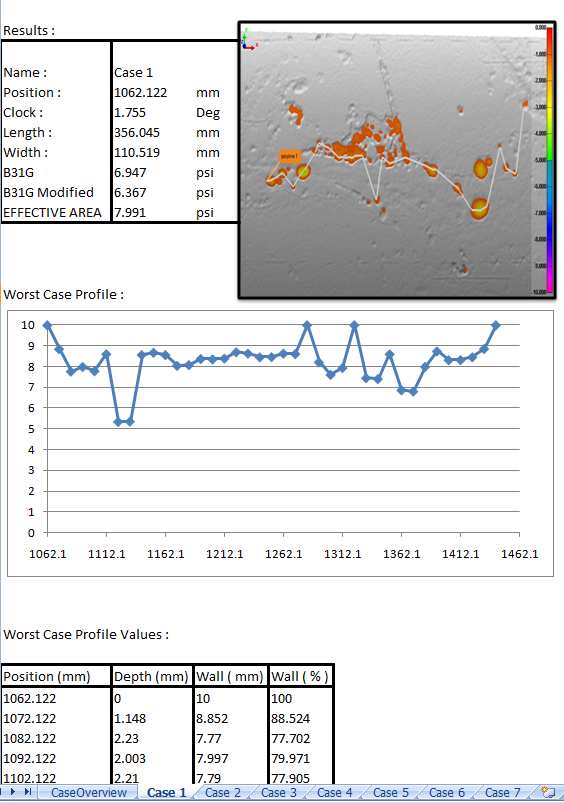

- Corrosion depth measurement, dimensions and positions on the pipe

- Scan areas in minutes instead of hours

- Accurate to 50 microns

- Estimated burst pressure calculations using methods based on ASME B31G code

For Pipelines most dig-ups can be reburied on the same day

- As soon as the wrapping is removed, we'll go to work.

- The external, and internal surface using the HydroFORM phased array system, are 100% scanned.

- Results emailed to you electronically on the same day with 3D imaging and Excel numerical results including assessment of results in accordance with ASME B31G code.

- The pipeline can be rewrapped and buried immediately in most cases.

ASME B31G integrity assessment analysis

For concrete testing we recommend

For concrete testing we recommend Geartest for specialised gear testing

Geartest for specialised gear testing